Crea Nest Expert is an advanced solution for automatic nesting in the upholstery industry, developed by Crea Solution's Systems.

By being a direct converter of native files – from many CAD Systems, and of standard files – from all applications compatible with the DXF–AAMA standard format, it can also be used in combination with other CAD products, different from Crea Solution's.

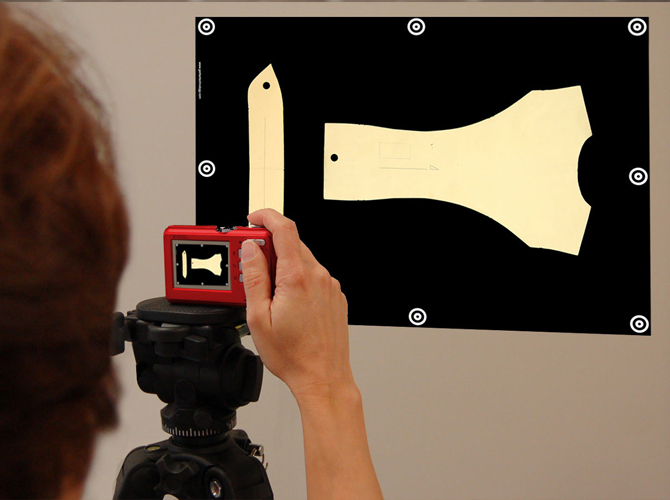

Crea Nest Expert is now prepared to be used in the process of creating ready-to-print markers, by having the capability of importing and nesting shapes with textures included, from the PDF file format.

The nesting results, in terms of speed and efficiency, are considerably higher than in the case of manual nesting.

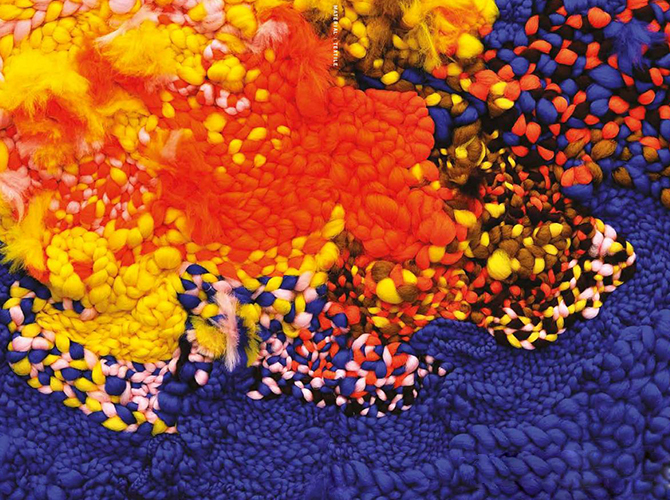

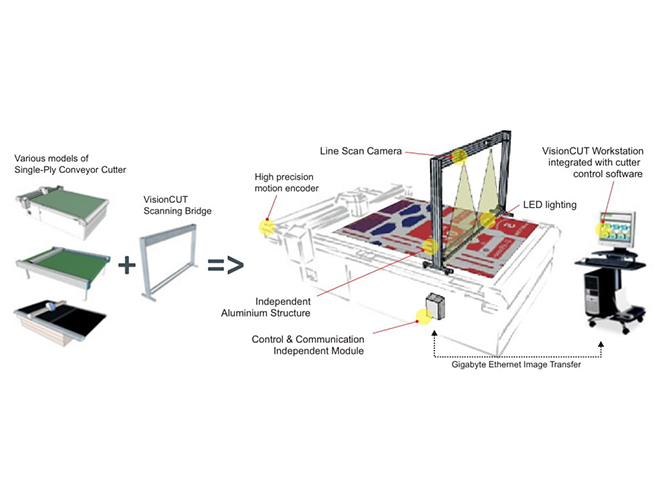

Crea Nest Expert can perform a fully automatic nesting for simple fabrics or for fabrics with plaids, stripes or textures, with specific widths and contractions, according to each piece specifications and freedom. Crea Nest Expert can output the nesting results in its own file format: *.mrk, but it can also export it in all major industry standards: DXF-AAMA, HPGL-PLT, ISO-CUT and RS274D. After the automatic nesting, the markers can be directly plotted or sent to the automatic cutting machine.

Nest Expert General Features

- Fully automatic, high-efficiency marker optimization

- Special features developed, dedicated to the upholstery industry, as is the case of the automatic nesting for checked fabrics

- Import of native files from Lectra, Gerber, Assyst and Investronica

- Import of standard files from any CAD System capable of outputting a standard file format

- Import of PDF files for the preparation of ready-to-print fileS

- Export to plotters, cutters

- Data import from ERP systems

- Data export to ERP systems

Automatic Nesting Server for Lay Assyst, Gerber Accumark and Lectra

- Based on the Crea Nest Expert state-of-the-art nesting technology

- Performs a fully automatic, high-efficiency marker optimization in 3-5 minutes

- Direct import and processing of Assyst/Gerber/Lectra markers from a local area network

- Direct export for the Assyst/Gerber/Lectra/Bullmer cutters and plotters

- Delivered “Ready-to-Work”, all software preinstalled and configured

- Available in all languages