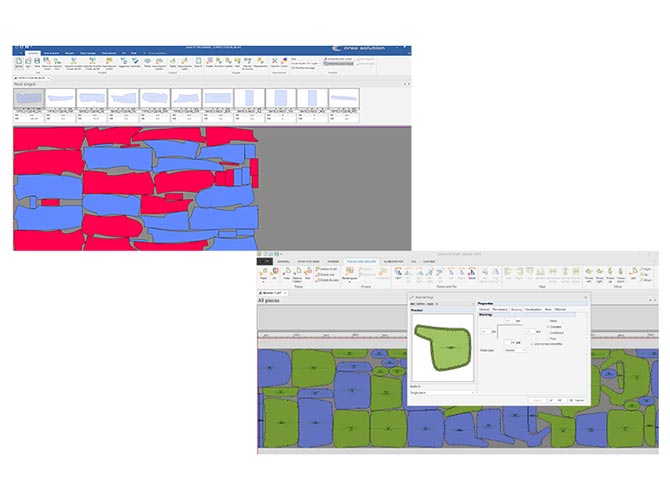

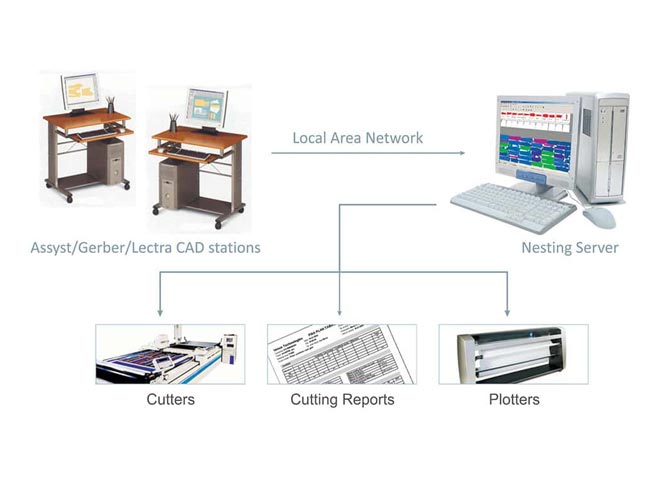

Crea Nest Expert holds since 2009 a leading position in terms of efficiency and speed of its automatic nesting module. This performance was achieved due the proprietary nesting algorithms, based on multi-core parallel processing, which later evolved to multi-machine nesting and the apparition of nesting servers and nesting farms. Crea Solution's is a pioneer in this field, being the first one to propose such solutions for nesting flexible materials.

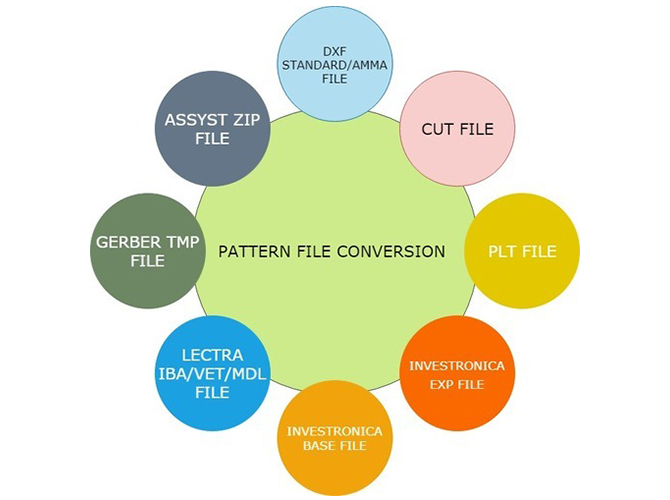

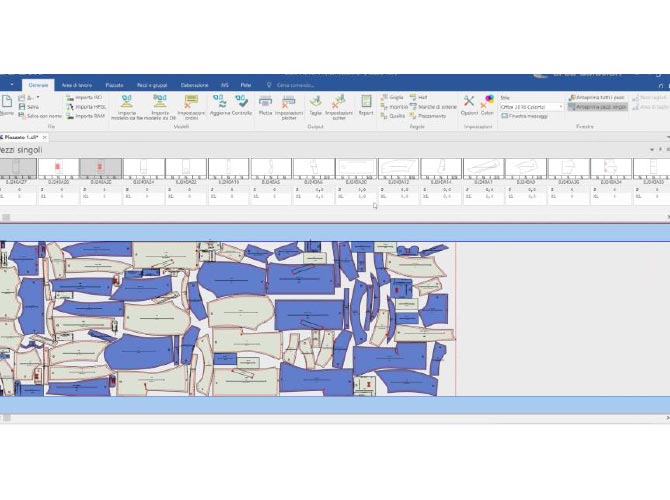

Crea Nest Expert can perform fully automatic nesting on simple, folded or tubular fabrics, with or without plaids, stripes or textures or shading, with specific widths and contractions, according to each part specifications and freedom. Crea Nest Expert can output the nesting results in all major industry standards: DXF-AAMA,

HPGL-PLT, ISO-CUT and RS274D. After the automatic nesting, the markers can be directly plotted or sent to the automatic cutting machine.

Crea Nest Expert features the unique ability to import and nest graphical content (ready-to-print PDF and EPS files), performing the function of an imposition software application for Digital Textile Printing. It can send the nested result directly to a wide format digital printer and to a single ply cutter with VisionCUT scanning system.

Based on its ability to import native marker and pattern files from other CAD systems, Crea Nest Expert can be used as a nesting server by companies operating on other CAD solution with less efficient automatic nesting.

Nest Expert General Features

- Fully automatic, high-efficiency marker optimization

- Special features developed, dedicated to apparel industry, such as: automatic nesting for checked fabrics and for tubular or folded fabrics, the fusing-block definition

- Import of standard DXF,PLT, ISO-CUT files

- Import of PDF files for the preparation of ready-to-print files

- Export to plotters, cutters

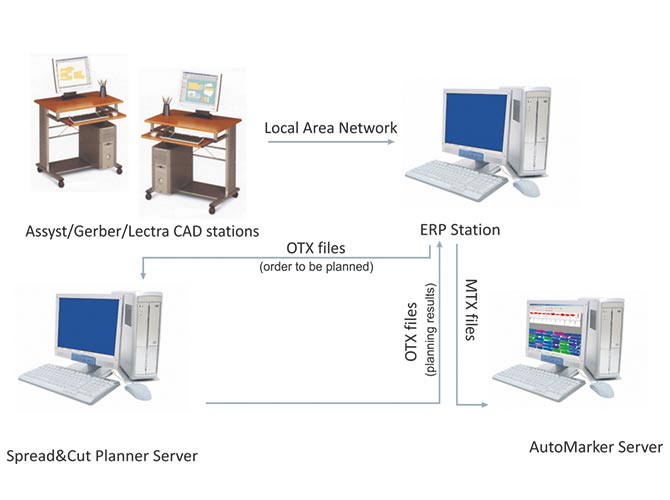

- Data exchange with ERP systems

Most of nesting applications use only one core of the processor, Crea MultiCore Automatic nesting uses all cores of the processor.